This is what you need to consider in the implementation

How complex the transition from barcode to 2D code is depends largely on the individual circumstances, the objectives and the choice of product. For example, it is much easier to change the barcodes on a product where it is not integrated into the packaging layout but applied in the form of an adhesive label.

For a product like washing powder, where the EAN/UPC barcode has already been pre-printed on the empty packaging, the implementation is much more complicated. The only practical way would probably be to replace the barcode with GS1 DataMatrix codes that include a serial number in addition to the GS1 article number. In this way, the packaging can continue to be pre-printed, albeit with higher demands on the printing process and the filling process. In production, the packages are then filled as usual and the additional data is subsequently linked to the serial numbers in the ERP/PIM. However, this circumstance requires an exchange of master data at serial number level with the retail partners, who must then also be able to retrieve this data at all necessary points (such as the checkout environment).

Use our blueprints as a guide

In order to support you optimally during the implementation, we have developed blueprints for you. Please contact us if you need an additional blueprint.

| Blue Print |

is being or has been piloted at |

Complexity |

|

|---|---|---|---|

| Replace EAN/UPC barcode with GS1 DataMatrix |

|

low |

|

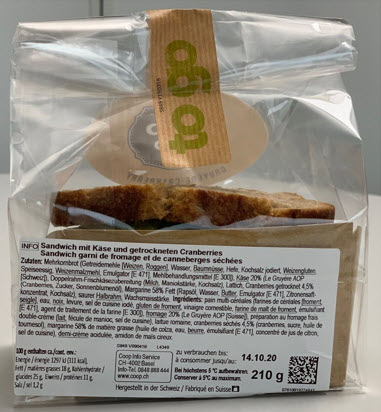

| Replace EAN/UPC barcode with GS1 DataMatrix for piece goods | Coop | medium | |

| Replace EAN/UPC barcode with GS1 DataMatrix for variable-quantity fresh products | GS1 Belgilux | medium | |

| Add EAN/UPC barcode with QR code and GS1 Digital Link | low | ||

| Supplement or replace EAN/UPC barcode or GS1 DataMatrix with QR Code and GS1 Digital Link | high | ||

| General serialization of products | high |

Blue Print: Replace EAN/UPC barcode with GS1 DataMatrix

Goals

- Reduction of the space required for the GS1 data carrier

- Use at the checkout (Point Of Sale) and in self-scanning

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the transition.

- Define a schedule with your partners.

- Replace the EAN/UPC barcode with the GS1 DataMatrix code.

- Document your experience and the requirements that need to be met in your operation in order to start pilot projects with a trading partner.

Blue Print: Replace EAN/UPC barcode with GS1 DataMatrix for piece goods

Goals

- Add additional data such as MHD, batch number in the 2D code with the help of the GS1 Application Identifier (AI).

- Use at the checkout (Point Of Sale) and self-scanning

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the conversion.

- Determine with your trading partner what additional data should be encoded in the 2D code in addition to the mandatory GS1 article number (GTIN).

- Consider the production process of the selected products and ensure that the additional data such as the BBD is available in the printing process.

- Contact your solution provider for the printing process and clarify whether the existing solution is capable of printing the necessary data in a GS1 DataMatrix.

- Check how you can cover the different requirements of your trading partners in your own production.

- Define a schedule with your partners.

- Replace the EAN/UPC barcode with the GS1 DataMatrix code.

- Document your experiences and the requirements that need to be met in your operation in order to start pilot projects with a trading partner.

Blue Print: Replace EAN/UPC barcode with GS1 DataMatrix for variable-quantity fresh products

Goals

- Use of the GS1 article number (GTIN) instead of the nationally unique GS1 article number (RCN) at best.

- Bar coding of product weight or individual price for quantity-variable fresh products

- Replacement of EAN/UPC barcodes by GS1 DataMatrix

- Using GS1 Application Identifier (AI) to add additional data such as MHD, batch number in 2D code

- Use at the checkout (Point Of Sale) and self-scanning

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the conversion.

- Determine with your trading partner what additional data should be encoded in the 2D code in addition to the mandatory GS1 article number (GTIN).

- Consider the production process of the selected products and ensure that the additional data such as the BBD is available in the printing process.

- Contact your solution provider for the printing process and clarify whether the existing solution is capable of printing the necessary data in a GS1 DataMatrix.

- Check how you can cover the different requirements of your trading partners in your own production.

- Define a schedule with your partners.

- Replace the EAN/UPC barcode with the GS1 DataMatrix code.

- Document your experiences and the requirements that need to be met in your operation in order to start pilot projects with a trading partner.

Blue Print: Add QR Code and GS1 Digital Link to EAN/UPC Barcode

Goals

- Supplement EAN/UPC barcodes with QR codes that can be used for consumer engagement

- Add additional data such as MHD, batch number in the 2D code using the GS1 Digital Link standard

- Specify which web page is displayed if a consumer scans the QR code with their cell phone

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the extension.

- Determine for your company what additional data should be encoded in the 2D code in addition to the mandatory GS1 article number (GTIN). This depends on the consumer needs you want to cover.

- Consider the production process of the selected products and make sure that the additional data is available in the printing process or can be pre-printed.

- Contact your solution provider for the printing process and clarify whether the existing solution is capable of printing the necessary data in a QR code. Take into account the space requirements.

- Add the QR code and GS1 Digital Link to the EAN/UPC barcode.

- Document your experience and the requirements that must be met in your operation in order to be able to start pilot projects with a trading partner.

Blue Print: supplement or replace EAN/UPC barcode or GS1 DataMatrix with QR code and GS1 Digital Link

Goals

- Add or replace EAN/UPC barcodes or GS1 DataMatrix with QR codes that can be used for consumer engagement

- Add additional data such as MHD, batch number in the 2D code using the GS1 Digital Link standard

- Determine which web page is displayed if a consumer scans the QR code with their cell phone

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the extension.

- Determine for your company what additional data should be encoded in the 2D code in addition to the mandatory GS1 article number (GTIN). This depends on the consumer needs you want to cover and the requirements of your trading partners.

- Consider the production process of the selected products and ensure that the additional data is available or can be pre-printed in the printing process.

- Contact your solution provider for the printing process and clarify whether the existing solution is capable of printing the necessary data in a QR code.

- Replace the EAN/UPC barcode or GS1 DataMatrix with the QR code and GS1 Digital Link.

- Document your experience and the requirements that need to be met in your operation in order to start pilot projects with a trading partner.

Blue Print: General serialization of products

Goals

- Serialization of all products so that additional data can be exchanged with trading partners as consumer unit master data

- Most precise tracking and traceability

Steps

- Together with the supply chain partners involved in the process, determine which products are suitable for testing the extension.

- Determine for your company which and how the additional data should be exchanged as master data in addition to the serialized GS1 article number (SGTIN) encoded in the 2D code. This depends on the consumer needs you want to cover and the requirements of your trading partners.

- Consider the production process of the selected products and ensure that the additional data can be captured based on the serial numbers.

- Contact your solution provider for the printing process and master data exchange and clarify whether the existing solutions are capable of covering the necessary processes.

- Start serializing your products.

- Document your experiences and the requirements that must be met in your operation in order to start pilot projects with a trading partner.